|

Proposed Comprehensive Development at Wo Shang Wai Yuen Long |

|

|

Certification by

Environmental Team Leader and Verification by Independent Environmental Checker

|

Contents |

Chapter Title Page

Tables

Figures

Figure 1.1 General Layout Plan of the Project Site

Figure 2.1 Locations of Air Quality Monitoring Stations

Figure 2.2 Locations of Noise Monitoring Stations

Figure 2.3 Locations of Water Quality Monitoring Stations

Figure 4.1 Survey Area and Transect Walked

Figure 4.2 Water Quality Monitoring Locations for Ecological Monitoring

Appendices

Appendix A

Project Organization

Chart

Appendix B Tentative Construction Programme

Appendix C

Action and Limit Levels

for Construction Phase

Appendix D

Event and Action Plan

for Air Quality, Noise, Water Quality and Landscape & Visual

Appendix E

Calibration Certificates

Appendix F

Graphical Plots of

the Monitoring Results

Appendix G

Weather Conditions

during the Monitoring Period

Appendix H

Ecological Monitoring

Conducted

Appendix I

Summary of Bird Surveys Conducted

Appendix J

Summary of Herpetofauna, Mammal and Insect Surveys Conducted

Appendix K

Summary of Monitoring of

Water Quality associated with Ecological Monitoring Conducted

Appendix L

Environmental

Mitigation Measures - Implementation Status

Appendix M

Landscape and Visual

Audit Photos

Mott MacDonald Hong Kong Ltd. (“MMHK”) has been commissioned by Heng Shung Construction Co. Ltd. to undertake the Environmental Team (ET) services to carry out environmental monitoring and audit (EM&A) for both pre-construction and construction phases of the Proposed Comprehensive Development at Wo Shang Wai, Yuen Long.

This is the 71st EM&A report submitted under the Condition 4.5 of Environmental Permit No. EP-311/2008/D. This report summarises the findings on EM&A during the period from 1 to 31 March 2016.

Exceedance of Action and Limit Levels

There was no breach of Action or Limit levels for Air Quality (1-hr TSP and 24-hr TSP) and Noise level (as Leq) in the reporting month.

During March 2016, a total of ten Action Level exceedances for Water Quality were observed. Ten Action Level exceedances of pH were observed at MP3, and no exceedances were observed at MP4, MP5 and MP6.

The summary of measured water quality is presented in Section 3.2.3.

Investigations have been carried out to identify the causes of exceedance. From investigation, the Contractor has implemented water quality mitigation measures as recommended in the EIA report. With external factors affecting the adjacent environments, such as pond fish culture activities, therefore all the recorded exceedances in Water Quality were considered not due to the project construction works.

Implementation of Mitigation Measures

Site audits were carried out on 1, 8, 15, 22 and 29 March 2016 to confirm the implementation measures undertaken by the Contractor in the reporting month. The outcomes are presented in Section 6 and the status of implementation of mitigation measures in the site is shown in Appendix L.

Record of Complaints

There was no new record of complaints received in the reporting month.

1

Introduction

|

1.1

Introduction

In March 2005, the Project Proponent, Profit Point Enterprises Limited, acquired the development site at Wo Shang Wai in Yuen Long. An Environmental Impact Assessment (EIA) was then carried out and approved under the EIA Ordinance (EIAO), and the Environmental Permit (EP-311/2008) for construction of the comprehensive development in Wo Shang Wai was first granted by EPD on 9 September 2008 and has been subsequently varied, with the current version (EP-311/2008/D) issued by EPD on 20 March 2013.

The Project involves the residential development and associated infrastructure and wetland restoration area and linear landscape area. The construction works under the Environmental Permit commenced on 12 May 2010. The site formation construction works of the Wetland Restoration Area (hereafter WRA) were completed on 15 November 2010, while the 30-month establishment period of the WRA was concluded in August 2012 – this indicated that planting works as scheduled in the approved Wetland Restoration and Creation Scheme (WRCS; Nov 2009) was complete, except along the western and southern boundary where the planting is affected by the existing site boundary and noise barrier, and for which a Variation to Environmental Permit (EP-311/2008/C) to defer planting at the location was approved. The current valid EP (EP-311/2008/D) includes specific mitigation measures to minimise certain identified noise impacts during the operation phase.

Mott MacDonald Hong Kong Ltd. (“MMHK”) has been commissioned by the Contractor, Heng Shung Construction Co. Ltd., to undertake the Environmental Team (ET) services to carry out environmental monitoring and audit (EM&A) for both pre-construction and construction phases of the Proposed Comprehensive Development at Wo Shang Wai, Yuen Long.

According to the EP Condition 4.5, the monthly EM&A Report shall be submitted to the Director within two weeks after the end of the reporting month. This report summarises the findings during the period from 1 to 31 March 2016.

1.2

Project Organization

The organisation chart and lines of communication with respect to the on-site environmental management structure together with the contact information of the key personnel are shown in Appendix A.

1.3

Environmental Status in the reporting period

During the reporting month, construction works of the Project undertaken include:

¡ No construction site works

¡ Pond drainage management in the Wetland Restoration Area (to lower the water level and remove unwanted species in the pond)

The Construction Works Programme of the Project is provided in Appendix B. The general layout plan of the Project site is shown in Figure 1.1.

1.4

Summary of EM&A Requirements

The EM&A programme requires environmental monitoring of air quality, noise, water quality, ecology and landscape and visual as specified in the approved EM&A Manual.

A summary of impact EM&A requirements is presented in Table 1.1 below:

Table 1.1: Summary of Impact EM&A Requirements

|

Parameters |

Descriptions |

Locations |

Frequencies |

|

Air Quality |

24-Hour TSP |

ASR1, ASR2A, ASR3, ASR4 |

Once every 6 days |

|

1-Hour TSP |

ASR1, ASR2A, ASR3, ASR4 |

3 times every 6 days |

|

|

Noise |

Leq, 30min |

NSR1, NSR3, NSR5, NSR7 |

Weekly |

|

Water Quality |

Dissolved Oxygen (DO), temperature, pH, suspended solids (SS) and Biological Oxygen Demand (BOD) |

MP1 to MP6 |

3 days per week |

|

Ecology |

Birds |

Within the Project Area and Assessment Area of 500m |

Weekly |

|

Dragonflies and Butterflies |

Within the Project Area and Assessment Area of 500m |

Once per month during Mar and Sep to November, and twice per month during Apr to Aug |

|

|

Herpetofauna |

Within the Project Area and Assessment Area of 500m |

Once per month during Apr to Nov |

|

|

Water quality of Wetland Restoration Area (WRA) |

WRA |

After filling of WRA with water, monthly for in situ water quality and every size months (end of wet season and end of dry season) for laboratory testing |

|

|

Site Inspections |

Within the Project Area and Assessment Area of 500m |

Weekly |

|

|

Landscape and Visual |

Auditing of protection of existing trees, the transplanting of existing trees, the creation of new wetland, the planting of new trees and shrubs and other landscape and visual mitigation measures |

CM1 to CM10 and OM1 to OM7 within the Project Area |

Site inspections once every two weeks during construction phase; once every two months during operational phase |

The Environmental Quality Performance Limits for air quality, noise and water quality are shown in Appendix C.

The Event and Action Plan for air quality, noise, water quality and Landscape & Visual are shown in Appendix D.

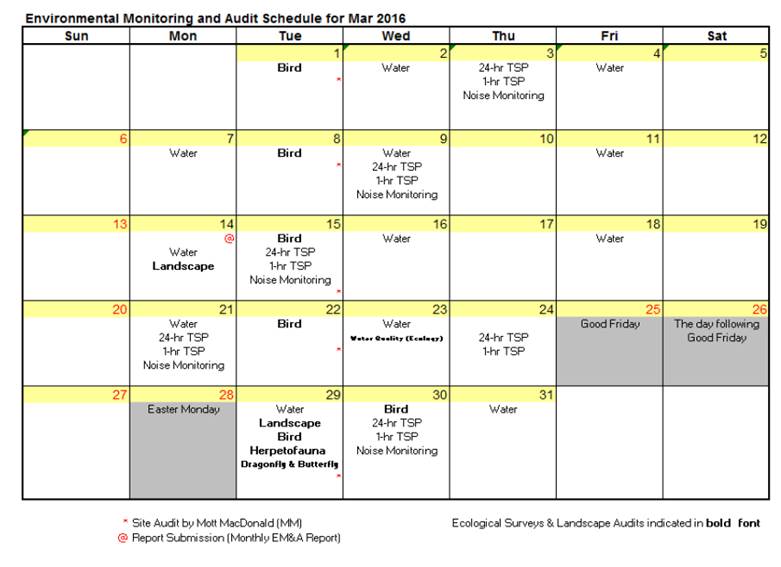

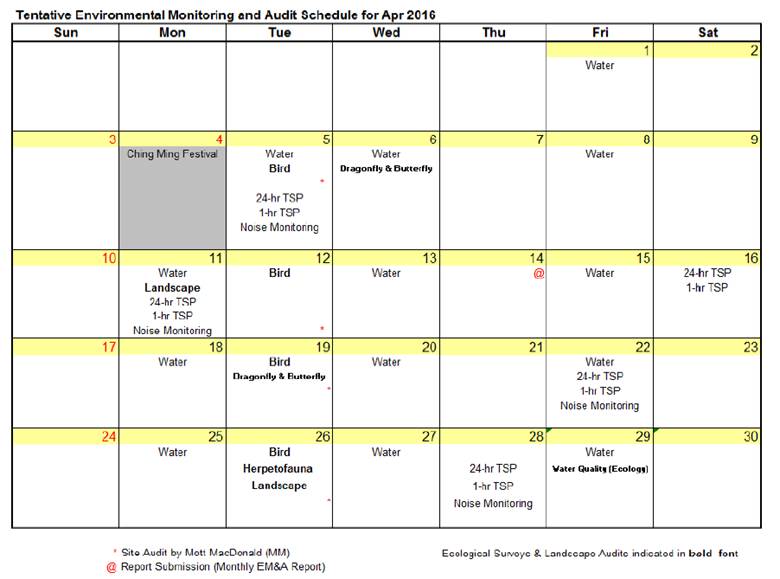

The monitoring schedule for the reporting month is shown in Table 1.2 below.

Table 1.2: Environmental Monitoring and Audit Schedule for the Reporting Month

2.1

Introduction

For air quality, construction noise and water quality, ecology, landscape and visual monitoring methodology, including the monitoring locations, monitoring equipment used, monitoring parameters, and frequency and duration, etc., are detailed in this Chapter.

2.2

Air Quality

2.2.1

Monitoring

Parameters, Frequency and Duration

In accordance with the EM&A Manual, 1-hour and 24-hour TSP levels monitoring are to be conducted during the construction phase. Table 2.1 summarizes the monitoring parameters, frequency and duration of air quality monitoring.

Table 2.1: Air Quality Monitoring Parameters, Frequency and Duration

|

Monitoring Stations |

Parameter |

Frequency and Duration |

|

ASR1, ASR2A, ASR3 & ASR4 |

24-hour TSP |

At least once in every six-days |

|

1-hour TSP |

3 times every six-days |

2.2.2

Monitoring

Locations

The four air quality monitoring stations were established in the EM&A manual and were slightly adjusted during the baseline monitoring phase. Locations of the agreed air quality monitoring stations are listed in Table 2.2 and as shown in Figure 2.1.

Table 2.2: Air Monitoring Stations

|

Monitoring Stations |

Locations |

|

ASR1 |

Works Site Boundary |

|

ASR2A |

At the rooftop of refuse collection point, which is located at the southwest of the project area |

|

ASR3 |

At the commercial centre at Palm Springs, which is located at the south of the project area |

|

ASR4 |

Works Site Boundary |

2.2.3

Monitoring

Equipment

Continuous 24-hour TSP air quality monitoring is conducted using High Volume Sampler (HVS) (Model: GMWS-2310 Accu-vol). The HVS meets all the requirements of the EM&A Manual. Portable direct reading dust meters were used to carry out the 1-hour TSP monitoring. Table 2.3 summarizes the equipment used in the impact air quality monitoring.

Table 2.3: TSP Monitoring Equipment

|

Equipment |

Model |

|

24-hr TSP monitoring |

|

|

High Volume Sampler |

GMWS 2310 Accu-vol |

|

Calibrator |

GMW 25 |

|

1-hr TSP monitoring |

|

|

Portable direct reading dust meter |

AM510 SidePak Personal Aerosol Monitor Dust Trak 8520 |

2.2.4

Monitoring

Methodology

2.2.4.1

24-hour TSP

Monitoring

Installation

The HVS was installed in the vicinity of the air sensitive receiver. The following criteria were considered in the installation of the HVS.

¡ A horizontal platform with appropriate support to secure the sampler against gusty wind was provided.

¡ The distance between the HVS and any obstacles, such as buildings, was at least twice the height that the obstacle protrudes above the HVS.

¡ A minimum of two metres separation from walls, parapets and penthouse was required for rooftop sampler.

¡ A minimum of two metres separation from any supporting structure, measured horizontally was required.

¡ No furnace or incinerator flues or building vent were nearby.

¡ Airflow around the sampler was unrestricted.

¡ The sampler has been more than 20 metres from any drip line.

¡ Permission was obtained to set up the samplers and to obtain access to the monitoring stations.

¡ A secured supply of electricity is needed to operate the samplers.

Preparation of Filter Papers

¡ Glass fibre filters were labelled and sufficient filters that were clean and without pinholes were selected.

¡ All filters were equilibrated in the conditioning environment for 24 hours before weighing. The conditioning environment temperature was around 25 °C and not variable by more than ±3 °C with relative humidity (RH) < 50% and was not variable by more than ±5%. A convenient working RH was 40%.

Field Monitoring

¡ The power supply was checked to ensure the HVS works properly.

¡ The filter holder and the area surrounding the filter were cleaned.

¡ The filter holder was removed by loosening the four bolts and a new filter, with stamped number upward, on a supporting screen was aligned carefully.

¡ The filter was properly aligned on the screen so that the gasket formed an airtight seal on the outer edges of the filter.

¡ The swing bolts were fastened to hold the filter holder down to the frame. The pressure applied should be sufficient to avoid air leakage at the edges.

¡ The shelter lid was closed and was secured with the aluminium strip.

¡ The HVS was warmed-up for about 5 minutes to establish run-temperature conditions.

¡ A new flow rate record sheet was set into the flow recorder.

¡ The flow rate of the HVS was checked and adjusted at around 1.1 m3/min. The range specified in the EM&A Manual was between 0.6-1.7 m3/min.

¡ The programmable timer was set for a sampling period of 24 hrs + 1 hr, and the starting time, weather condition and the filter number were recorded.

¡ The initial elapsed time was recorded.

¡ At the end of sampling, the sampled filter was removed carefully and folded in half length so that only surfaces with collected particulate matter were in contact.

¡ It was then placed in a clean plastic envelope and sealed.

¡ All monitoring information was recorded on a standard data sheet.

¡ Filters were sent to a HOKLAS accredited laboratory for analysis.

Maintenance and Calibration

¡ The HVS and its accessories are maintained in good working condition, such as replacing motor brushes routinely and checking electrical wiring to ensure a continuous power supply.

¡ HVSs were calibrated at two-month intervals.

¡ Calibration records for HVSs are shown in Appendix E.

2.2.4.2

1-hour TSP

Monitoring

Field Monitoring

The measuring procedures of the 1-hour dust meter are in accordance with the Manufacturer’s Instruction Manual as follows:

¡ Set POWER to “ON”, push BATTERY button, make sure that the meter’s indicator is in the range with a red line and allow the instrument to stand for about 3 minutes (Then, the air sampling inlet has been capped).

¡ Push the knob at MEASURE position.

¡ Push “O-ADJ” button. (Then meter’s indication is 0).

¡ Push the knob at SENSI ADJ position and set the meter’s indication to S value described on the Test Report using the trimmer for SENSI ADJ.

¡ Pull out the knob and return it to MEASURE position.

¡ Push “START” button.

Maintenance and Calibration

¡ The 1-hour dust meter would be checked at 3-month intervals and calibrated at 1-year intervals throughout all stages of the air quality monitoring.

¡ Calibration records for direct dust meters are shown in Appendix E.

2.3

Construction Noise

2.3.1

Monitoring

Parameters, Frequency and Duration

Following the requirements in the EM&A Manual for noise, noise monitoring has to be carried out during the construction phase. Continuous noise monitoring for the A-weighted levels Leq, L10 and L90 is undertaken once per every week.

Table 2.4 summarizes the monitoring parameters, frequency and duration of air quality monitoring.

Table 2.4: Noise Monitoring Parameters, Frequency and Duration

|

Monitoring Stations |

Parameter |

Frequency and Duration |

|

NSR1, NSR3, NSR5, NSR7 |

Leq, L90 & L10 |

Once every week |

2.3.2

Monitoring

Locations

The four noise quality monitoring stations were established in the EM&A manual and were slightly adjusted during the baseline monitoring phase. Locations of the agreed noise quality monitoring stations are listed in Table 2.5 and as shown in Figure 2.2.

Table 2.5: Noise Monitoring Stations

|

Monitoring Stations |

Locations |

Type of measurement |

|

NSR1 |

Noise monitoring equipment was set up near the boundary wall at Palm Springs. |

Free-field |

|

NSR3 |

The monitoring station was located next to the guard house at Palm Springs. |

Facade |

|

NSR5 |

The monitoring station was located within the work site boundary. |

Free-field |

|

NSR7 |

The monitoring station was located near the boundary wall of the house of Mai Po San Tsuen. |

Free-field |

2.3.3

Monitoring

Equipment

Integrating Sound Level Meter will be used for noise monitoring. It is a Type 1 sound level meter capable of giving a continuous readout of the noise level readings including equivalent continuous sound pressure level (Leq) and percentile sound pressure level (Lx). They comply with International Electrotechnical Commission Publications 651:1979 (Type 1) and 804:1985 (Type 1). Table 2.6 summarizes the noise monitoring equipment model being used.

Table 2.6: Noise Monitoring Equipment

|

Equipment |

Model |

|

Integrating Sound Level Meter |

Rion NL-52 |

|

Calibrator |

Rion NC-73 |

2.3.4

Monitoring

Methodology

Field Monitoring

¡ The Sound Level Meter was set on a tripod at a height of at least 1.2 m above the ground.

¡ Façade and free-field measurements were made at the monitoring locations.

¡ The battery condition was checked to ensure the correct functioning of the meter.

¡ Parameters such as frequency weighting, the time weighting and the measurement time were set as follows:

– frequency weighting: A

– time weighting: Fast

– time measurement: 30 minutes intervals (between 07:00 and 19:00)

¡ Prior to and after each noise measurement, the meter was calibrated using a Calibrator for 94 dB at 1 kHz. If the difference in the calibration level before and after measurement was more than 1 dB, the measurement would be considered invalid has to be repeated after re-calibration or repair of the equipment.

¡ During the monitoring period, the Leq, L10 and L90 were recorded. In addition, any site observations and noise sources were recorded on a standard record sheet.

Maintenance and Calibration

¡ The microphone head of the sound level meter and calibrator is cleaned with soft cloth at quarterly intervals.

¡ The meter and calibrator are sent to the supplier or HOKLAS laboratory to check and calibrate at yearly intervals.

¡ Calibration records are shown in Appendix E.

2.4

Water Quality

2.4.1

Monitoring Parameters,

Frequency and Duration

In accordance with the requirements in the EM&A Manual for water quality, water quality parameters including Dissolved Oxygen (DO), temperature, pH, turbidity, suspended solids (SS) and Biochemical Oxygen Demand (BOD) have to be monitored at designated monitoring stations during construction of the Project. DO, temperature and pH were measured in-situ whereas SS and BOD were analysed in a laboratory. The measurements should be taken at all designated monitoring stations, three days per week. The interval between any two sets of monitoring was not less than 36 hours. Table 2.7 summarizes the monitoring parameters, frequency and duration of water quality monitoring.

Table 2.7: Water Quality Monitoring Parameters, Frequency and Duration

|

Monitoring Stations |

Parameter |

Frequency and Duration |

|

MP1, MP2, MP3, MP4, MP5 & MP6 |

DO, temperature, pH, SS, turbidity, BOD |

Three days every week |

2.4.2

Monitoring

Locations

The six water quality monitoring stations were established in the EM&A manual. Locations of the agreed water quality monitoring stations are listed in Table 2.8 and as shown in Figure 2.3.

Table 2.8: Water Quality Monitoring Stations

|

Monitoring Stations |

Easting |

Northing |

|

MP1 |

838 730.50 |

822 862.25 |

|

MP2 |

838 933.26 |

823 247.41 |

|

MP3 |

839 107.17 |

823 596.84 |

|

MP4 |

839 286.14 |

823 638.55 |

|

MP5 |

839 134.35 |

823 722.99 |

|

MP6 |

839 063.02 |

823 842.25 |

2.4.3

Monitoring

Equipment

The Water Quality Monitoring Equipment and Analytical Methods applied to Water Quality Samples are given in Table 2.9 and Table 2.10 respectively. Details of which are discussed below.

Table 2.9: Water Quality Monitoring Equipment

|

Equipment |

Model |

Equipment/Serial Number |

|

Conductivity, Dissolved oxygen, pH, Salinity and Temperature Measuring Meter |

YSI Professional Plus |

10D101565 |

|

Turbidity Meter |

Hach 2100Q |

13120C004242 |

|

Global Positioning System (GPS) |

Garmin eTrex Vista |

ENO 007 |

Table 2.10: Analytical Methods applied to Water Quality Samples

|

Determinant, unit |

Standard Method |

|

Total Suspended Solids, mg/L |

In house method based on APHA 2540D; ALS Method Code: EA-025 |

|

Biochemical Oxygen Demand (BOD), mg/L |

In house method based on APHA 5210B; ALS Method Code: EP-030 |

All in-situ monitoring instruments were checked, calibrated and certified by a laboratory accredited under HOKLAS or any other international accreditation scheme before use.

Dissolved Oxygen (DO), Temperature and pH measuring equipment

A portable, weatherproof multiparameter instrument (YSI Professional Plus) was used in the monitoring. It can be capable for measuring dissolved oxygen (DO), pH, and temperature simultaneously with the following limits:

¡ a dissolved oxygen level in the range of 0-50 mg/L and 0-500 % saturation;

¡ a temperature of -5 to 45 degrees Celsius; and

¡ pH value of 0-14 with 0.1 as the base unit.

Turbidity Measurement Instrument

Portable and weatherproof turbidity meter (HACH model 2100Q IS) was used during impact monitoring. It has a photoelectric sensor capable of measuring turbidity between 0-1000 NTU. Response of the sensor was checked with certified standard turbidity solutions before the start of measurement.

Global Positioning System (GPS)

A hand-held GPS navigator (Garmin eTrex Vista) was used to identify the designated monitoring stations prior to water sampling.

Suspended Solids and BOD Measurements (Sample Containers and Storage)

Water samples for SS analysis were stored in high density polythene bottles with no preservative added, packed in ice (cooled to 4 ºC without being frozen), delivered to the laboratory, and analysed as soon as possible after collection. Analysis was carried out in a HOKLAS accredited laboratory.

2.4.4

Detection Limit

The limits of detection for the in-situ and laboratory measurements are shown in Table 2.11.

Table 2.11: Detection Limits for Water Quality Determinants

|

Determinant |

Limit of Detection |

|

Dissolved Oxygen |

0.1 mg/L |

|

Temperature |

0.1 degree Celsius |

|

pH |

0.01 unit |

|

Turbidity |

0.1 NTU |

|

Suspended Solids |

1 mg/L |

|

BOD |

2 mg/L |

2.4.5

Monitoring

Methodology

In situ Measurement

All pH meters, DO/temperature meters had been checked and calibrated prior to use. Standard buffer solution of at least two pH levels (either pH 4 and pH 7, or pH 7 and pH 10) had been used for calibration of the instrument before and after use.

DO meters had been calibrated by a laboratory accredited under HOKLAS or any other international accreditation scheme, and subsequently re-calibrated at three-monthly intervals throughout all stages of the water quality monitoring. Responses of sensors and electrodes had been checked with certified standard solutions before each use. Wet bulb calibrations for all DO meters had been carried out before measurement at each monitoring location. For the on-site calibration of field equipment, BS 127:1993, "Guide to field and on-site test methods for the analysis of waters" had been observed.

Measurements shall be at three water depths, namely, 1m below water surface, mid-depth and 1m above stream bed/pond bed, except where the water depth less that 6m, the mid-depth station maybe omitted. Should the water depth be less than 3 m, only the mid-depth station will be monitored.

Replicates in-situ measurements and samples collected from each independent monitoring event are required for all parameters to ensure a robust statistically interpretable dataset.

Water Samples Preparation and Analysis

For collection of water sampling within the water courses, a 500ml clean plastic beaker was used. After collection, the water samples were stored in high-density polythene bottles. The sample container was rinsed with a portion of the water sample. The water sample was then transferred to the container, labelled with a unique sample ID and sealed with a screw cap. The water samples were stored in a cool box maintained at 4 ºC. The water samples were then delivered to a local HOKLAS-accredited laboratory (ALS) on the same day for analysis.

The testing methods of testing parameters as recommended by EIA or required by EPD, with the QA/QC results are in accordance with the requirement of HOKLAS or international accredited scheme.

The calibration certificates for equipment used for in-situ monitoring of water quality are attached in Appendix E.

2.5

Ecology

2.5.1

Monitoring

Parameters, Frequency and Duration

Target species and certain other fauna will be monitored within the Project Area and Assessment Area during the wetland and residential construction phase. This will be important to ensure that any unexpected events or impacts either on- or off-site are quickly identified so that remedial action can be taken. The groups to be monitored and frequency of monitoring are shown in Table 2.12.

Table 2.12: Summary of Construction Phase Ecological Monitoring for the Wo Shang Wai Wetland Restoration Area (WRA)

|

Species / Parameter |

Construction Phase Ecological Monitoring |

|

Birds |

Weekly (including Assessment Area). |

|

Dragonflies and Butterflies |

Once per month during March and September to November, and twice per month during April to August. |

|

Herpetofauna |

Once per month during April to November. |

|

Water Quality |

After filling of WRA with water, monthly for in situ water quality and every six months (end of the wet season and end of the dry season) for laboratory testing. |

|

Site Inspections |

Weekly. |

2.5.2

Monitoring

Locations and Methodology

Ecological monitoring locations during construction phase are shown in Figure 4.1 and the methodology for ecological monitoring is detailed in Section 4.

2.6

Landscape and Visual

2.6.1

Monitoring

Parameters, Frequency and Duration

All measures undertaken by both the Contractor and the specialist Landscape Sub-Contractor during the construction phase and first year of the operational phase shall be audited by a Registered Landscape Architect, as a member of the ET, on a regular basis to ensure compliance with the intended aims of the measures. Site inspections should be undertaken at least once every two weeks throughout the construction period and once every two months during the operational phase.

The broad scope of audit is detailed below but should also be undertaken with reference to the more specific checklist provided in Table 2.13 below. Operational phase auditing will be restricted to the last 12 months of the establishment works of the landscaping proposals and thus only the items below concerning this period are relevant to the operational phase.

¡ The extent of the agreed works area should be regularly checked during the construction phase. Any trespass by the Contractor outside the limit of the works, including any damage to existing trees and woodland shall be noted;

¡ The progress of the engineering works should be regularly reviewed on site to identify the earliest practical opportunities for the landscape works to be undertaken;

¡ All existing vegetation, streams and other features within the study area which are not directly affected by the works are retained and protected;

¡ The methods of protecting existing vegetation proposed by the Contractor are acceptable and enforced;

¡ Preparation, lifting transport and re-planting operations for any transplanted trees;

¡ The layout, design and construction of buildings conforms to requirements specified in the EIA report;

¡ All landscaping works are carried out in accordance with the EIA recommendations and with specifications;

¡ The planting of new trees, shrubs, groundcover, climbers, grasses and other plans, together with the replanting of any transplanted trees are carried out properly and within the right season;

¡ All necessary horticultural operations and replacement planting are undertaken throughout the Establishment Period to ensure the healthy establishment and growth of both transplanted trees and all newly establishment plants.

Table 2.13: Construction and Operation Phase Audit Checklist

|

Area of Works |

Items to be Monitored |

|

Works Area |

Check the extent of the Works to ensure that the Works Area is not exceeded |

|

Protection of all trees and woodland blocks to be retained |

Identification and demarcation of trees / vegetation to be retained, erection of physical protection (e.g. fencing), monitoring against possible incursion, physical damage, fire, pollution, surface erosion, etc. |

|

Streams |

Ensure no run-off into existing streams |

|

Clearance of existing vegetation |

Identification and demarcation of trees / vegetation to be cleared, checking of extent of works to minimize damage, monitoring of adjacent areas against possible incursion, physical damage, fire, pollution, surface erosion, etc. |

|

Transplanting of trees |

Identification and demarcation of trees / vegetation to be transplanted, monitoring of extent of pruning / lifting works to minimize damage, timing of operations implementation of all stages of preparatory and translocation works, and maintenance of transplanted vegetation, etc. |

|

Topsoil stripping |

Ensuring existing topsoil is stripped and stored under recognized good practice and is hydroseeded and regularly turned to prevent anaerobic conditions |

|

New buildings |

Ensure that building finishes accord with mitigation proposals with regard to colour and albedo. |

|

Boundaries |

Ensuring hoarding are erected as required |

|

Noise Barrier |

Ensure noise barrier design accords with the mitigation proposals with regard to location, materials and finishes. |

|

Night-time lighting |

Ensuring night-time lighting is directional, hooded and shielded away from VSRs |

|

Plant supply |

Monitoring of operations relating to the supply of specialist plant material (including the collecting, germination and growth of plants from seed) to ensure that plants will be available in time to be used within the construction works. |

|

Landscape and wetland treatments generally |

Check that wetland, and hard / soft landscape designs conform to intent of mitigation measures and agreed designs |

|

Soiling, planting, etc. |

Monitoring of implementation and maintenance of soiling and planting works against possible incursion, physical damage, fire, pollution, surface erosion, etc. |

|

Establishment Works |

Monitoring of implementation of maintenance operation during Establishment Period |

2.6.2

Monitoring

Locations

The monitoring locations should check against the mitigation measures proposed under the approved Environmental Impact Assessment, which are summarised as follows in Table 2.14 and Table 2.15:

Table 2.14: Proposed Construction Phase Mitigation Measures

|

ID No. |

Landscape and Visual Mitigation Measures |

|

CM1 |

The construction area and contractor’s temporary works areas should be minimised to avoid impacts on adjacent landscape. |

|

CM2 |

Screening of construction works by hoardings/noise barriers around Works area in visually unobtrusive colours, to screen Works. |

|

CM3 |

Reduction of construction period to practical minimum. |

|

CM4 |

Topsoil, where identified, should be stripped and stored for re-use in the construction of the soft landscape works, where the soil material meets acceptable criteria and where practical. The Contract Specification shall include storage and reuse of topsoil as appropriate. |

|

CM5 |

Hydroseeding or sheeting of soil stockpiles with visually unobtrusive material (in earth tone). |

|

CM6 |

Advance screen planting to noise barriers. |

|

CM7 |

Control night-time lighting and glare by hooding all lights. |

|

CM8 |

Ensure no run-off into streams adjacent to Project Area. |

|

CM9 |

Protection of existing trees on boundary of project area shall be carefully protected during construction. Detailed Tree Protection Specification shall be provided in the Contract Specification. Under this specification, the Contractor shall be required to submit, for approval, a detailed working method statement for the protection of trees prior to undertaking any works adjacent to all retained trees, including trees in contractor’s works areas. (Tree protection measures will be detailed at S16 and Tree Removal Application stage). |

|

CM10 |

Trees unavoidably affected by the works shall be transplanted where practical. Trees should be transplanted straight to their destinations and not held in a nursery. A detailed Tree Transplanting Specification shall be provided in the Contract Specification, if applicable. Sufficient time for necessary tree root and crown preparation periods shall be allowed in the project programme. |

Table 2.15: Proposed Operation Phase Mitigation Measures

|

ID No. |

Landscape Mitigation Measures |

|

OM1 |

Compensatory Tree Planting for all felled trees shall be provided to the satisfaction of relevant Government departments. Required numbers and locations of compensatory trees shall be determined and agreed separately with Government during the Tree Felling Application process under ETWBTC 3/2006. |

|

OM2 |

A continuous belt of screen planting along southern perimeter of project area with fast growing tree species. At least 450 trees capable of reaching a height > 10m within 10 years should be planted. Planting of the belt of trees shall be carried out as advance works ahead of other site formation and building works. |

|

OM3 |

Maximise soft landscape and amenity water bodies in residential areas of the development. Approximately 750 trees (of Heavy Standard size) should be planted. Where space permits, roadside berms should be created. Street trees should be of species that reach a mature height of no less than 15m. |

|

OM4 |

Maximise freshwater habitat wetland creation consistent with achieving other parameters. Minimum 4.74 ha to be provided. Wetlands must have natural edge profiles with >1m wide emergent zone. No access to the wetland by residents and all wetlands must be screened from residential development by a continuous tree screen at interface with residential development or earth mounding such that disturbance is minimised. Implementation of the wetland shall be carried out as advance works. |

|

OM5 |

Use appropriate (visually unobtrusive and non-reflective) building materials and colours in built structures. |

|

OM6 |

During detailed design, refine building layout to create a min. 10m wide gap between buildings north of Wo Shang Wai pond and also two min. 10m wide gaps in the row of buildings adjacent to Royal Palms. |

|

OM7 |

Streetscape elements (e.g. paving, signage, street furniture, lighting etc.) shall be sensitively designed in a manner that responds to the local context, and minimises potential negative landscape and visual impacts. Lighting units should be directional and minimise unnecessary light spill. |

3

Monitoring

Results

|

3.1

Impact Monitoring Schedule

Impact monitoring for air quality (dust), noise and water quality due to the construction work were undertaken during the reporting month in compliance with the EM&A manual in the reporting period. Regular site inspections were carried out on 1, 8 and 15 March 2016 during the reporting month to assess the compliance with environmental requirements.

3.2

Results of Impact Monitoring

3.2.1

Air Quality

Monitoring

3.2.1.1

1-hour TSP

Results of 1-hour TSP at the four monitoring locations are summarised in Table 3.1. Graphical plots of the monitoring results are shown in Appendix F. The weather conditions in the reporting period are provided in Appendix G.

Table 3.1: Summary of 1-hour TSP Monitoring Results

|

Monitoring |

Start Time |

1-hr TSP (mg/m3) |

Range |

Action Level |

Limit Level |

||

|

Date |

|

1st Result |

2nd Result |

3rd Result |

(mg/m3) |

(mg/m3) |

(mg/m3) |

|

ASR1 |

|

|

|

|

|

|

|

|

03-Mar-16 |

11:34 |

132 |

113 |

106 |

70-148 |

378 |

500 |

|

09-Mar-16 |

11:23 |

102 |

95 |

78 |

|||

|

15-Mar-16 |

11:26 |

77 |

71 |

70 |

|||

|

21-Mar-16 |

11:32 |

98 |

92 |

88 |

|||

|

24-Mar-16 |

10:36 |

142 |

148 |

143 |

|||

|

30-Mar-16 |

10:44 |

114 |

80 |

105 |

|||

|

ASR2A |

|

|

|

|

|

|

|

|

03-Mar-16 |

08:20 |

71 |

81 |

84 |

50-162 |

357 |

500 |

|

09-Mar-16 |

09:11 |

50 |

59 |

74 |

|||

|

15-Mar-16 |

09:14 |

59 |

74 |

84 |

|||

|

21-Mar-16 |

09:18 |

56 |

60 |

60 |

|||

|

24-Mar-16 |

07:21 |

135 |

141 |

142 |

|||

|

30-Mar-16 |

07:30 |

148 |

162 |

162 |

|||

|

ASR3 |

|

|

|

|

|

|

|

|

03-Mar-16 |

08:13 |

74 |

70 |

70 |

67-148 |

358 |

500 |

|

09-Mar-16 |

09:03 |

67 |

70 |

70 |

|||

|

15-Mar-16 |

09:07 |

84 |

87 |

85 |

|||

|

21-Mar-16 |

09:13 |

77 |

76 |

76 |

|||

|

24-Mar-16 |

07:14 |

142 |

142 |

145 |

|||

|

30-Mar-16 |

07:21 |

135 |

148 |

147 |

|||

|

ASR4 |

|

|

|

|

|

|

|

|

03-Mar-16 |

11:27 |

111 |

95 |

101 |

69-199 |

372 |

500 |

|

09-Mar-16 |

11:17 |

73 |

69 |

83 |

|||

|

15-Mar-16 |

11:21 |

97 |

92 |

84 |

|||

|

21-Mar-16 |

11:26 |

99 |

97 |

91 |

|||

|

24-Mar-16 |

11:30 |

139 |

142 |

148 |

|||

|

30-Mar-16 |

10:39 |

199 |

122 |

105 |

|||

3.2.1.2

24-hour TSP

Results of 24-hour TSP at the four monitoring locations are summarised in Table 3.2. Graphical plots of the monitoring results are shown in Appendix F. The weather conditions in the reporting period are provided in Appendix G.

Table 3.2: Summary of 24-hour TSP Monitoring Results

|

Monitoring Date |

Monitoring Results (mg/m3) |

Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

ASR1 |

|

|

|

|

|

03-Mar-16 |

60 |

60-86 |

226 |

260 |

|

09-Mar-16 |

76 |

|||

|

15-Mar-16 |

73 |

|||

|

21-Mar-16 |

78 |

|||

|

24-Mar-16 |

72 |

|||

|

30-Mar-16 |

86 |

|||

|

ASR2A |

|

|

|

|

|

03-Mar-16 |

63 |

63-75 |

213 |

260 |

|

09-Mar-16 |

69 |

|||

|

15-Mar-16 |

75 |

|||

|

21-Mar-16 |

68 |

|||

|

24-Mar-16 |

74 |

|||

|

30-Mar-16 |

74 |

|||

|

ASR3 |

|

|

|

|

|

03-Mar-16 |

63 |

63-84 |

205 |

260 |

|

09-Mar-16 |

79 |

|||

|

15-Mar-16 |

82 |

|||

|

21-Mar-16 |

72 |

|||

|

24-Mar-16 |

75 |

|||

|

30-Mar-16 |

84 |

|||

|

ASR4 |

|

|

|

|

|

03-Mar-16 |

52 |

52-83 |

237 |

260 |

|

09-Mar-16 |

83 |

|||

|

15-Mar-16 |

76 |

|||

|

21-Mar-16 |

69 |

|||

|

24-Mar-16 |

69 |

|||

|

30-Mar-16 |

83 |

No exceedance of 1-hour and 24-hour TSP (Action or Limit Level) was recorded in the reporting period.

3.2.2

Construction

Noise Monitoring

The construction noise monitoring results are summarized in Table 3.3. Graphical plots of the monitoring data are shown in Appendix F. The weather conditions in the reporting period are provided in Appendix G.

Table 3.3: Summary of Construction Noise Monitoring Results

|

Monitoring Date |

Start Time |

Mean and Range of Noise Levels, dB(A) |

Limit Level for Leq (dB(A)) |

||

|

|

|

Leq |

L10 |

L90 |

|

|

NSR1 |

|

|

|

|

|

|

03-Mar-16 |

10:03 |

51 |

53 |

40 |

>75 |

|

09-Mar-16 |

11:24 |

51 |

53 |

46 |

|

|

15-Mar-16 |

11:17 |

51 |

52 |

48 |

|

|

21-Mar-16 |

11:27 |

55 |

56 |

54 |

|

|

30-Mar-16 |

09:10 |

46 |

48 |

41 |

|

|

NSR3 |

|

|

|

|

|

|

03-Mar-16 |

10:37 |

53 |

56 |

40 |

>75 |

|

09-Mar-16 |

10:47 |

48 |

50 |

45 |

|

|

15-Mar-16 |

10:42 |

49 |

51 |

48 |

|

|

21-Mar-16 |

10:52 |

54 |

56 |

53 |

|

|

30-Mar-16 |

09:48 |

47 |

49 |

45 |

|

|

NSR5 |

|

|

|

|

|

|

03-Mar-16 |

08:41 |

52 |

55 |

43 |

>75 |

|

09-Mar-16 |

09:26 |

48 |

50 |

45 |

|

|

15-Mar-16 |

09:30 |

54 |

57 |

50 |

|

|

21-Mar-16 |

09:34 |

55 |

55 |

54 |

|

|

30-Mar-16 |

07:48 |

46 |

48 |

42 |

|

|

NSR7 |

|

|

|

|

|

|

03-Mar-16 |

09:18 |

66 |

68 |

63 |

>75 |

|

09-Mar-16 |

10:07 |

67 |

69 |

65 |

|

|

15-Mar-16 |

10:04 |

66 |

68 |

64 |

|

|

21-Mar-16 |

10:10 |

67 |

68 |

66 |

|

|

30-Mar-16 |

08:24 |

67 |

68 |

64 |

|

No exceedance (Action/Limit Level) of construction noise was recorded in the reporting period.

3.2.3

Water Quality

Monitoring

The water quality monitoring results are summarized in Table 3.4. Graphical plots of the monitoring data are shown in Appendix F. The weather conditions in the reporting period are provided in Appendix G.

Table 3.4: Summary of Water Quality Monitoring Results

|

Monitoring Date |

Temp (ºC) |

pH |

Dissolved Oxygen (DO) (mg/L) |

DO (%) |

Turbidity (NTU) |

BOD (mg/L) (1) |

Suspended Solids (mg/L) |

|

MP3 |

|

|

|

|

|

|

|

|

02/03/2016 |

20.3 |

7.6 |

8.3 |

92.0 |

27.6 |

7 |

27 |

|

04/03/2016 |

18.7 |

7.5 |

8.3 |

88.6 |

26.8 |

6.5 |

19.5 |

|

07/03/2016 |

19.9 |

7.6 |

8.5 |

93.0 |

52.5 |

14 |

44.5 |

|

09/03/2016 |

18.3 |

7.6 |

8.3 |

88.1 |

46.7 |

18 |

41 |

|

11/03/2016 |

16.9 |

7.6 |

8.8 |

90.5 |

58.1 |

8.5 |

50.5 |

|

14/03/2016 |

17.9 |

7.6 |

9.0 |

94.8 |

37.5 |

8.5 |

33.5 |

|

16/03/2016 |

21.2 |

7.6 |

8.1 |

90.6 |

38.1 |

7 |

34 |

|

18/03/2016 |

20.3 |

7.5 |

7.8 |

86.5 |

38.9 |

6.5 |

36 |

|

21/03/2016 |

18.5 |

7.6 |

8.3 |

88.3 |

36.2 |

9.5 |

35.5 |

|

23/03/2016 |

17.5 |

7.6 |

8.8 |

91.5 |

26.6 |

10 |

22.5 |

|

29/03/2016 |

19.9 |

7.6 |

7.9 |

86.3 |

41.9 |

14.5 |

36 |

|

31/03/2016 |

22.1 |

7.6 |

7.7 |

88.4 |

47.5 |

24.5 |

43 |

|

Action Level |

- |

<5.5 or >7.5 |

<6.85 |

- |

>64 |

- |

>65 |

|

Limit Level |

- |

<4.0 or >8.0 |

<6.65 |

- |

>67 |

- |

>66 |

|

|

|

|

|

|

|

|

|

|

MP4 |

|

|

|

|

|

|

|

|

02/03/2016 |

19.7 |

7.4 |

7.4 |

81.4 |

8.3 |

2 |

10 |

|

04/03/2016 |

18.1 |

7.4 |

8.0 |

84.1 |

9.2 |

2 |

5 |

|

07/03/2016 |

20.3 |

7.4 |

7.5 |

83.3 |

12.1 |

2 |

12 |

|

09/03/2016 |

17.9 |

7.5 |

8.7 |

91.7 |

9.0 |

<2 |

6.5 |

|

11/03/2016 |

16.3 |

7.5 |

8.5 |

86.6 |

9.1 |

<2 |

8 |

|

14/03/2016 |

17.5 |

7.5 |

8.5 |

89.2 |

9.5 |

<2 |

10 |

|

16/03/2016 |

20.9 |

7.5 |

8.5 |

95.0 |

9.0 |

2 |

6.5 |

|

18/03/2016 |

20.7 |

7.4 |

7.4 |

82.5 |

17.4 |

<2 |

16.5 |

|

21/03/2016 |

18.1 |

7.5 |

8.1 |

86.0 |

33.4 |

3 |

25 |

|

23/03/2016 |

17.9 |

7.5 |

8.0 |

83.9 |

46.3 |

3 |

36 |

|

29/03/2016 |

19.3 |

7.5 |

8.0 |

87.1 |

13.5 |

3 |

12.5 |

|

31/03/2016 |

21.8 |

7.5 |

7.3 |

83.6 |

28.8 |

3 |

13 |

|

Action Level |

- |

<5.5 or >7.5 |

<3.91 |

- |

>60 |

- |

>50 |

|

Limit Level |

- |

<4.0 or >8.0 |

<3.82 |

- |

>64 |

- |

>53 |

|

|

|

|

|

|

|

|

|

|

MP5 |

|

|

|

|

|

|

|

|

02/03/2016 |

19.4 |

7.4 |

7.7 |

84.6 |

9.4 |

2.5 |

10 |

|

04/03/2016 |

18.4 |

7.4 |

8.1 |

86.2 |

17.3 |

4.5 |

12.5 |

|

07/03/2016 |

19.5 |

7.4 |

7.8 |

85.3 |

28.8 |

7 |

26.5 |

|

09/03/2016 |

17.7 |

7.5 |

8.3 |

87.5 |

25.9 |

10 |

24 |

|

11/03/2016 |

16.5 |

7.5 |

8.1 |

82.6 |

30.2 |

6 |

28.5 |

|

14/03/2016 |

17.3 |

7.5 |

8.1 |

84.5 |

17.6 |

4 |

16 |

|

16/03/2016 |

20.6 |

7.4 |

7.8 |

87.8 |

28.7 |

6 |

26.5 |

|

18/03/2016 |

20.5 |

7.4 |

7.5 |

84.4 |

23.5 |

3 |

20.5 |

|

21/03/2016 |

17.8 |

7.4 |

9.0 |

94.8 |

27.9 |

5.5 |

26 |

|

23/03/2016 |

18.2 |

7.4 |

9.0 |

96.2 |

41.1 |

7 |

27 |

|

29/03/2016 |

19.1 |

7.4 |

7.6 |

83.5 |

20.4 |

7 |

18 |

|

31/03/2016 |

21.6 |

7.5 |

7.6 |

86.6 |

33.2 |

13 |

22.5 |

|

Action Level |

- |

<5.5 or >7.5 |

<4.13 |

- |

>81 |

- |

>66 |

|

Limit Level |

- |

<4.0 or >8.0 |

<3.87 |

- |

>84 |

- |

>69 |

|

|

|

|

|

|

|

|

|

|

MP6 |

|

|

|

|

|

|

|

|

02/03/2016 |

18.9 |

7.4 |

7.9 |

85.6 |

9.1 |

2 |

10.5 |

|

04/03/2016 |

18.5 |

7.4 |

7.7 |

82.8 |

16.9 |

5 |

11.5 |

|

07/03/2016 |

19.5 |

7.4 |

8.4 |

91.9 |

28.6 |

8 |

27.5 |

|

09/03/2016 |

17.5 |

7.5 |

8.3 |

87.4 |

25.5 |

10 |

23.5 |

|

11/03/2016 |

16.1 |

7.5 |

8.8 |

89.7 |

28.9 |

6 |

29 |

|

14/03/2016 |

17.1 |

7.5 |

7.8 |

81.8 |

17.9 |

4 |

17 |

|

16/03/2016 |

20.7 |

7.4 |

7.4 |

82.6 |

28.4 |

5.5 |

26 |

|

18/03/2016 |

20.4 |

7.4 |

7.2 |

80.5 |

23.2 |

3 |

22.5 |

|

21/03/2016 |

17.9 |

7.4 |

8.6 |

91.5 |

27.6 |

5.5 |

24.5 |

|

23/03/2016 |

18.1 |

7.4 |

8.2 |

87.6 |

41.5 |

7 |

28 |

|

29/03/2016 |

19.0 |

7.4 |

7.7 |

83.4 |

20.1 |

6.5 |

18 |

|

31/03/2016 |

21.5 |

7.5 |

7.8 |

88.8 |

33.5 |

12.5 |

23.5 |

|

Action Level |

- |

<5.5 or >7.5 |

<4.61 |

- |

>94 |

- |

>75 |

|

Limit Level |

- |

<4.0 or >8.0 |

<4.52 |

- |

>96 |

- |

>75 |

Notes:

(1) “<2 “ : Value is too low to indicate (<2mg/L).

(2) Values Bold indicate Action Level exceedance.

(3) Values Underlined and Bold indicate Limit Level exceedance.

3.2.3.1

Exceedance

Investigation and Findings

During March 2016, a total of ten Action Level exceedances for Water Quality were observed. Ten Action Level exceedances of pH were observed at MP3; no exceedances were observed at MP4, MP5 and MP6.

The Event and Action Plan in Appendix D was followed under these cases of exceedances.

Based on the recent site observations carried out by ET, the Contractor implemented the following water quality mitigation measures as recommended in EIA report which include:

¡ Temporary drainage channels were provided to collect the surface runoff generated within the project site; and

¡ Installation of barrier at the drainage channels to intercept site runoff and pump the wastewater to the sedimentation tanks as primary treatment prior to treatment by wastewater treatment facilities (AquaSed), which will ensure all site runoff is treated to satisfactory quality before discharging into the northern ditches.

Exceedance of pH at MP3

During the reporting month at MP3, exceedances of the Action Level of pH were observed on ten monitoring dates. As understood, the fish pond near the site (represented by MP3) was being separated from the construction site by the WRA since November 2010, so the exceedance(s) were not considered to be related to the construction activities. The exceedances of pH may be due to external factors such as pond fish culture activities which were out of the control of the project.

Conclusion

As a result, the abovementioned exceedance(s) were unlikely to be due to the construction works and therefore not considered to be related to the project.

4.1

Monitoring of Birds

This report documents surveys conducted in the Survey Area between 1 and 31 March 2016. The Wetland Restoration Area (WRA) is also surveyed as the area is accessible and site formation works for WRA has been completed. The updated survey transect is provided in Figure 4.1. Dates and ecological surveys conducted during this period are summarised in Appendix H.

Monitoring was undertaken following the survey methodology in the EM&A Manual. A transect was followed in the bird surveys (see Figure 4.1). All bird species were identified to species and all bird species of conservation importance and/or wetland dependent were enumerated and recorded to the habitats in which they were observed. Flying birds were not recorded unless they were foraging and/or associated with the habitat (such as swifts). Further, notable bird observations during other surveys were also recorded.

Bird surveys were conducted on a weekly basis. A total of 43 bird species was recorded in the Survey Area (excluding the WRA), 22 of which were species of conservation importance and/or wetland-dependence. Within the WRA, 42 bird species were recorded, 18 of which were species of conservation importance and/or wetland-dependence including two of the target species (i.e. Little Egret and Chinese Pond Heron). The WRA continues to attract a number of species of conservation importance, including Great Cormorant, Phalacrocorax carbo, Northern Shoveler, Anas clypeata, Yellow Bittern, Ixobrychus sinensis, Black Kite, Milvus migrans, Crested Serpent Eagle, Spilornis cheela, Zitting Cisticola, Cisticola juncidis, , Chinese Penduline Tit, Remiz consobrinus, and Collared Crow, Corvus torquatus. Yellow Bittern, Crested Serpent Eagle, Zitting Cisticola and Collared Crow are listed by Fellowes et al. as of “Local Concern” in 2002. Northern Shoveler, Black Kite, and Chinese Penduline Tit are listed by Fellowes et al. as of “Regional Concern” in 2002. Great Cormorant is listed by Fellowes et al. as of “Potential Regional Concern” in 2002. In addition to wetland-dependence birds, the WRA also attracts a number of terrestrial birds including Greater Coucal, Centropus sinensis which are listed as vulnerable (VU) in the China Red Data Book and it is protected under terrestrial wildlife state protection (category II). Survey findings indicate that the WRA not only provides important habitat for wetland-dependence birds but also the terrestrial birds.

A summary of survey data is provided in Appendix I.

4.2

Monitoring of Herpetofauna

One night time herpetofauna survey was conducted in the reporting month. No amphibian species or reptile species were recorded in other surveys.

A summary of the survey findings is provided in Appendix J.

4.3

Monitoring of Dragonflies and Butterflies

Odonatas and butterflies surveys were conducted on a monthly basis according to the EM&A Manual. No odonatas and butterfly species were recorded in the Survey Area during the regular survey. Within the WRA, no odonatas species were recorded while two butterfly species were recorded during the regular survey.

A summary of the survey findings is provided in Appendix J.

4.4

Monitoring of Mammals

Monitoring of mammals was conducted concurrently with other surveys. No mammals were recorded in the Survey Area (excluding the WRA) nor within the WRA during the regular survey and additional night search.

A summary of the survey findings is provided in Appendix J.

4.5

Monitoring of Water Quality

No water quality issue was recorded during the reporting period. Monitoring data are presented in Appendix K. Locations for the monitoring of water quality for the ecological monitoring are shown in Figure 4.2.

4.6

Management Activities

4.6.1

Vegetation

Management

Removal of exotic vegetation in all cells was undertaken; these included but not limited to Ipomoes sp., Mikania sp., Mimosa sp., Pennisetum sp. and Typha sp..

Vegetation management activities undertaken at the site primarily involved watering of plants, weeding and grass cutting.

4.6.2

Wildlife

Management

Removal of Golden Apple Snail was undertaken on an “as-seen” basis.

All sighted Red Fire Ant nests were treated with approved pesticide.

4.7

Summary

Ecological monitoring during March 2016 was carried out according to the survey methodology and frequency outlined in the EM&A Manual.

Summary of survey findings is listed in Table 4.1 below:

Table 4.1: Summary of Ecological Monitoring in WRA and Survey Area

|

Species |

Survey Area (excluding WRA) |

WRA |

|

Birds (total) |

43 |

42 |

|

Birds (of conservation importance and/or wetland-dependence) |

22 |

18 |

|

Amphibians |

0 |

0 |

|

Reptiles |

0 |

0 |

|

Mammals |

0 |

0 |

|

Odonates |

0 |

0 |

|

Butterflies |

0 |

2 |

Survey findings indicate that the ponds within the Survey Area supported numbers and diversity of wetland-dependent birds typical of fish pond areas. The WRA continues to attract wetland dependent fauna and serves as a buffer between the residential portion and the fishponds in the north.

5.1

Site Inspections

The EM&A programme for Landscape and Visual impact due to the construction commenced in June 2010 and continued during the reporting period. Site inspections on Landscape and Visual impact were carried out on 14 and 29 March 2016 to confirm the implementation of mitigation measures at construction stage.

The Event and Action Plan for Landscape & Visual is shown in Appendix D.

5.2

Construction Phase Audit Summary

The audit was undertaken with references to the specific checklists provided in Table 2.13 – Table 2.15 and audit results are summarized below in Table 5.1. Representative photos showing the implementation of mitigation measures are presented in Appendix M.

Table 5.1: Construction and Operation Phase Audit Summary

|

Area of Works |

Items of be Monitored |

|

Works Area |

The

boundaries of the works area have been established on site in accordance with

the contract documents and approved plans (EP), and the limit of current

heavy construction activity is now confined to within the site hoardings

(North side of the site / access road) and the noise barriers (other sides of

the site). Minor works such as horticultural maintenance of the planting and

transplanted trees, and boundary fence repair was proceeding along the Royal

Palms – Palm Springs boundary. (Appendix M

Photo 1 – Table 2.14 CM2 refers) No

construction works were observed to have exceeded the site boundaries.

No construction was carried out at the wetland restoration area after 15

November 2010. |

|

Protection of all trees and woodland blocks to

be retained |

Trees

retained within the site along the northeast boundary, beside wetland

restoration area, have been identified and protected by temporary protective

fencing. |

|

Streams |

The

works site is partly encircled by a berm / perimeter channel to intercept

surface water and prevent it from washing off into any of the neighboring

sites. Surface water is collected within the site in a temporary

drainage channel. Gravels beds and barriers have been installed to

filter site runoff, sedimentation ponds have been provided to enable primary

treatment before discharge to mains drains. |

|

Clearance of existing vegetation |

Site

clearance was completed prior to the commencement of construction. |

|

Transplanting of trees |

Tree

transplanting has been completed, with the trees relocated to various points

within the planting strip along the southern boundary of the site, outside

the noise barrier. The trees continue to re-establish well. |

|

Topsoil stripping |

Suitable

pond bund and soil material which had been excavated and stockpiled from the

original site, has now been re-used within the

landscape works. Dust

suppression measures are active along all internal site access tracks. |

|

New buildings |

No

new permanent buildings have yet been constructed on site. |

|

Boundaries |

Hoardings

have been erected along most of the boundaries of the site.

Installation of new screen fence between the future residential sites and the

constructed wetland restoration areas is complete. Fence has been painted

green to match with the surrounding vegetated environment. (Appendix

M Photo 1 – Table 2.14 CM2 refers) |

|

Noise Barrier |

Noise

barriers have been installed along the southern and western boundaries of the

site in accordance with the contract requirements. Their design

complies with the mitigation requirements, with upper 6 to 7m portion of the

barrier being made from a translucent material with green tinted (to match

with the environment). Supporting GMS structure, likewise, has been painted

green. (Appendix M

Photo 3 – Table 2.14 CM6 refers) |

|

Night-time lighting |

No

night-time works were reported to have been carried out during the monitoring

period. |

|

Landscape and wetland treatments generally |

Continuous

belt of screen planting along the southern and western boundaries of the site

has been completed. The formation, soiling and water control structures

of the wetland restoration area have been completed. (Appendix

M Photo 3 – Table 2.14 CM6 refers) The

wetland areas are being established, with the ponds are being seasonally

filled with rain water. Planting of areas around the WRA cells is

complete. No construction was carried out at the wetland restoration

area after 15 November 2010. (Appendix M

Photo 2 – Table 2.14 CM2 refers) |

|

Soiling, etc. |

The

soiling for the advance planting strip has been completed. The soil

placement and grading for each of the wetland restoration areas has been

completed. |

|

Plant supply |

The

plant material used in the Advance Planting Strip and in the WRA are all

commonly available species and came from commercial sources. Transplanted

reeds (Phragmites australis) at the wetland habitat came from the

temporary holding nursery onsite. |

|

Planting |

The

tree species are all from the approved list. Some

of the tree that were identified as dead in the previous month or having

defects (i.e. extensive bark damage, cavities, fungal growths, etc.) still

need to be replaced with new specimens. Some of the recently planted trees

are still in poor condition, but are showing small signs of graduate

improvement. The

total number of trees that will reach a minimum of 10m in the advance

planting strip may not meet the contract requirements causing a potential

future problem if replanting of dead and defective trees is not undertaken in

a timely manner. Seedling

trees and shrubs, have been established at the margins

of the wetland cells. Some additional fill-in planting has been undertaken. |

|

Establishment Works |

The advance planting, the

compensatory planting and transplanted trees are generally being maintained

by the landscape sub-contractor in accordance with the specification to

ensure that the contract requirements are met, although treatment of damaged

/ defective trees needs urgent attention. Some of the trees that were

identified as dead in the previous month still need to be replaced with new

specimens. Trees with significant defects (i.e. extensive bark damage,

cavities, fungal growths, etc.) need to be replaced with new specimens. Most overhanging trees from adjacent

property that were affecting the strip planting have been pruned back. Many trees are growing (and have

become dependent for support) on the noise barrier frame, and are being

deformed and damaged. Trees should either be physically separated from the

structure, or the structure modified to avoid impacting on trees. Pruning of tall shrubs (e.g. Ligustrum sinensis)

needs to be undertaken regularly. Removal of extensive growth of weeds

and invasive climbers in the space behind screen noise barrier needs to be

undertaken on a monthly basis as they may be inhibiting the advance planting.

Climbers were still found on shrub plantings (i.e. Mikania

micranth) and railing, and should be cleared

immediately. Phragmites australis reeds are now occupying at least

80% of the reed bed areas within the WRC (as per design), but have also

spread to the non-reed bed areas and are out-competing the intended planting.

Management of this vegetation is required if the intended planting design is

to be achieved. Regular horticultural maintenance

(grass cutting, weeding, watering etc.) in the shrubs and tree seedling areas

around the WRA cells is being undertaken. A comprehensive tree survey has

just been undertaken by the new landscape contractor. The growth of shrubs / seedlings on

the north side of WRA1 remains fair. |

6

Environmental

Site Inspection and Audit

|

6.1

Site Inspection

The ET had carried out construction phase weekly site inspections on 1, 8, 15, 22 and 29 March 2016. All observations have been recorded in the site inspection checklist and passed to the Contractor together with the appropriate recommended mitigation measures where necessary. The key observations from site inspections and associated recommendations are summarized in Table 6.1.

Table 6.1: Summary of Site Inspections and Recommendations

|

Key Observations |

ET Recommendation |

Contractor’s Responses / Action(s) Undertaken |

Close-out (Date) |

|

Leakage of treated wastewater from the Wetsep was observed. (2, 18 and 23 February 2016)

|

The Contractor was reminded to make suitable repairs to prevent adverse water quality impact. |

Agreed and followed up |

1 March 2016 |

|

Damaged noise barrier was observed. (23 February 2016) |

The Contractor was reminded to repair the noise barrier to avoid noise leakage. |

Agreed and followed up |

1 March 2016 |

|

Accumulated mosses in sedimentation tank one was observed. (1 March 2016) |

The Contractor was reminded to clean up the mosses. |

Agreed and followed up |

8 March 2016 |

|

Oil leakage from maintenance of excavator was observed. (1 March 2016) |

The Contractor was reminded to remove affected soil and handle it as chemical waste. Suitable mitigation measures to control/prevent further oil leakage onto the soil should also be provided. |

Agreed and followed up |

8 March 2016 |

|

No labelling of Non-Road Mobile Machinery emission exemption for one excavator was observed. (8, 15 March 2016) |

The Contractor was reminded to display the exemption labels for all excavators on site. |

Agreed and followed up |

22 March 2016 |

|

A drip tray for a generator was not plugged and oil stain next to the drip tray was observed. (29 March 2016) |

The Contractor was asked to plug the drip tray and remove the oil stain as soon as possible. |

Agreed and action to be taken |

On going |

6.2

Solid and Liquid Waste Management Status

The Contractor has been registered as a chemical waste producer for the Project. Construction and demolition (C&D) material sorting was carried out on site. A sufficient number of receptacles were available for general refuse collection.

As advised by the Contractor, no C&D material was generated on site during the period. 2 kg of metals was generated and collected by registered recycling collector. 2 kg of paper/cardboard packing and 1 kg of plastic were generated on site and collected by registered recycling collector. No chemical waste was generated and collected by licensed chemical waste collector. 2 kg of other types of wastes (e.g. general refuse) was generated on site and disposed of at public landfill facility.

The Contractor is advised to maintain on site waste sorting and recording system and maximize reuse / recycling of C&D wastes.

6.3

Status of Environmental Licences and Permits

The environmental permits, licenses, and/or notifications on environmental protection for this Project which were valid during the reporting period is summarised in Table 6.2.

Table 6.2: Status of Environmental Submissions, Licenses and Permits

|

Statutory Reference |

Description |

Permit/Reference No. |

Status |

|

EIAO |

Environmental Permit |

EP-311/2008/D |

Valid |

|

APCO |

Notification of Construction Work under APCO |

316688 (27 Apr 2010) |

Valid |

|

WPCO |

Discharge License |

WT00022647-2015 (8 Oct 2015) |

Valid |

|

WDO |

Registration as Chemical Waste Producer |

WPN0000-542-H3083-04 |

Valid |

|

WDO |

Bill Account for Disposal |

700945423 |

Valid |

Legend: EIAO – Environmental Impact Assessment Ordinance; APCO – Air Pollution Control Ordinance; WPCO – Water Pollution Control Ordinance; WDO – Waste Disposal Ordinance

6.4

Recommended Mitigation Measures

The EM&A programme followed the recommended mitigation measures in the EM&A Manual. The EM&A requirements as well as the summary of implementation status of the environmental mitigation measures are provided in Appendix L. In particular, the following mitigation measures were brought to attention during the site audits.

Water Quality

¡ Site effluent should be discharged in accordance with discharge licence.

¡ The site should be confined and properly maintained to avoid silt runoff.

Waste Management

¡ The chemical waste storage area should be clearly labelled.

¡ General Refuse should be stored in enclosed bins or compaction units separate from C&D and chemical wastes.

7.1

Record of non-compliance of Action and Limit Levels

There was no breach of Action or Limit Levels for Air Quality and Noise monitoring in the reporting month.

During March 2016, a total of ten Action Level exceedances for Water Quality were observed. Ten Action Level exceedances of pH were observed at MP3; no exceedances were observed at MP4, MP5 and MP6.

A summary is presented in Table 7.1 below.

Table 7.1: Summary of Exceedances in Water Quality

|

Monitoring Date |

pH |

Dissolved Oxygen (DO) (mg/L) |

Turbidity (NTU) |

Suspended Solids (mg/L) |

|

MP3 |

|

|

|

|

|

02/03/2016 |

7.6 |

8.3 |

27.6 |

27 |

|

04/03/2016 |

7.5 |

8.3 |

26.8 |

19.5 |

|

07/03/2016 |

7.6 |

8.5 |

52.5 |

44.5 |

|

09/03/2016 |

7.6 |

8.3 |

46.7 |

41 |

|

11/03/2016 |

7.6 |

8.8 |

58.1 |

50.5 |

|

14/03/2016 |

7.6 |

9.0 |

37.5 |

33.5 |

|

16/03/2016 |

7.6 |

8.1 |

38.1 |

34 |

|

18/03/2016 |

7.5 |

7.8 |

38.9 |

36 |

|

21/03/2016 |

7.6 |

8.3 |

36.2 |

35.5 |

|

23/03/2016 |

7.6 |

8.8 |

26.6 |

22.5 |

|

29/03/2016 |

7.6 |

7.9 |

41.9 |

36 |

|

31/03/2016 |

7.6 |

7.7 |

47.5 |

43 |

|

Action Level |

<5.5 or >7.5 |

<6.85 |

>64 |

>65 |

|

Limit Level |

<4.0 or >8.0 |

<6.65 |

>67 |

>66 |

Notes:

(1) “<2 “ : Value is too low to indicate (<2mg/L).

(2) Values Bold indicate Action Level exceedance.

(3) Values Underlined and Bold indicate Limit Level exceedance.

7.2

Record on Environmental Complaints Received

No environmental complaint was received during the reporting month.

7.3

Record on Notifications of Summons and Successful

Prosecution

No notifications of summons or successful prosecution were received the reporting month.

7.4

Review of Reasons for and Implications of Non-compliance,

Complaints, Summons and Prosecutions

Non-compliance

Investigations have been carried out to identify the causes of the water quality exceedances.

From investigation, construction activities during the period of exceedance included mainly site formation as well as pond drainage management in the Wetland Restoration Area (to lower the water level and remove unwanted species in the pond).

The fish pond near the site (represented by MP3) was being separated from the construction site by the WRA since November 2010, so the exceedances of pH at MP3 were not considered to be related to the construction activities.

As a result, the abovementioned exceedance(s) were unlikely to be due to the project construction works and therefore not considered to be related to the project.

Complaints, Summons and Prosecutions

Not applicable for this reporting month.

7.5

Follow-up Actions Taken

Non-compliance

As non-compliances have been recorded, the Event and Action Plan has been followed. Although it is considered that the exceedances were not related to the Project, the Contractor was reminded to implement the water quality mitigation measures in accordance with the recommendation stated in Section 5.6.1 – 5.6.4 of the EIA Report as far as practicable and regular spot check would be conducted on the nearby discharge by Contractor and inform ET for investigation.

Complaints, Summons and Prosecutions

Not applicable for this reporting month.

7.6

Cumulative Statistics for Complaints, Notifications of

Summons and Successful Prosecutions

Cumulative statistics for complaints, notifications of summons and successful prosecutions for the Project account for period starting from the date of commencement of construction (i.e. 12 May 2010) to the end of the reporting month and are summarized in Table 7.2 below.

Table 7.2: Statistics for Complaints, Notifications of Summons and Successful Prosecution

|

Reporting Period |

Cumulative Statistics |

||

|

|

Complaints |

Notifications of Summons |

Successful Prosecutions |

|

This reporting month (March 2016) |